BPI NEWSLETTER

BPI NEWSLETTER

Dedicated to the art and

engineering of pore pressure prediction and potential drilling hazards.

Issue Number 1

Issue Number 1

WELCOME to the premier

issue of the Baird Petrophysical International, Inc. NewsLetter. This issue is dedicated to following

individuals who are pioneers in the pore pressure prediction field:

Eugene

S. Pennebaker Paul E.

Pilkington Leo J.

McClure

We hope you will join us in recognizing these individuals

and the significant contribution they made to our industry. This newsletter will routinely contain

articles written by several of these individuals especially for inclusion in

this newsletter. Some will be regular contributors

and some will be honored as guest writers.

We think you will agree that they offer some valuable viewpoints and

perspectives on the work that we are doing today.

This newsletter is designed for distribution by email and

snail mail. This keeps our costs

reasonable and insures timely delivery to you, while allowing you to easily

enroll (and remove) your name from our distribution via our Internet Home

Page. It further allows the recipients

to easily comment on the contents of this publication. If you do not find this newsletter valuable

and useful, interesting or anything else that would encourage your continued

enrollment, please send us you comments as this is a work in progress and will

improve and expand with time.

Figure 1. Eugene S. Pennebaker, Jr., Exxon Retiree, currently living in Corpus Christi,

Texas. Visited by BPI staff, April 28, 2000.

E. S. “Gene” PENNEBAKER, Jr.

Mr. Pennebaker contributed greatly as a pioneer to pore

pressure prediction. While employed at Humble Oil (now Exxon Mobil) Pennebaker

wrote the book on the utilization of seismic reflection data to identify and

quantify abnormal pressure, drilling rate of penetration and especially the

drilling parameters’ relationships to geologic age and seismic interval

velocity. BPI and McClure and Associates jointly refined, re-defined and

improved on the methods laid out by Pennebaker in 1965. Today with this first

issue of The BPI Newsletter, we salute Eugene S. Pennebaker, Jr. for his

contributions to drilling safety by use of pore pressure prediction. Please see

article below by Leo J. McClure, History and Pioneers of Pore Pressure

Prediction.

PRESSURE AND LOG PLOTTING AND REPORT STANDARDS

BPI NEWSLETTER will attempt to do some missionary work in

the area of standards --- standards for terminology, standards of plotting,

standards for interpretation processes, and standards in other areas that are

common to pore pressure understanding. Presently there exist no standards and

thus there is a lack of communication even within the pore pressure profession.

This has specifically caused misunderstanding and results that have been

subject to numerous misunderstood reports. We intend to propose BPI’s standards

to the industry because we believe that these standards are both useful and

necessary for the safety and efficiency of drilling of oil and gas wells. We

will show how the more common tools, such as overlays and well-to-well

comparisons, will be more universally applicable. This will lead to industry standards for this important wok, led

by BPI’s leadership in this area. Due to the obvious lack of standards, we

hereby solicit your candid comments and promise to address them in subsequent

issues. The result of this effort shall be a recommended set of standard

plotting scales and presentation formats. BPI will not let this issue rest

without a recommended solution.

PRACTICAL WELL PLANNING SOFTWARE

“Software is a tool and not a solution,” Jack D. Hall

“Computers, God’s gift to mankind?” Paul E. Pilkington

HISTORY AND PIONEERS OF PORE PRESSURE PREDICTION

by Leo J. McClure, Guest Columnist

Electrical log pore pressure plotting started in the early

1960’s by using the old “Electric Logs” of that era. The resistivity curve value was plotted on single cycle semi-log

paper with a depth scale of one inch equals 1,000 feet for depth and the

resistivities plotted by ohms or tenths of an ohm across the top of the

paper. This system worked fairly well

until industry started drilling deeper wells such as 15,000 to 16,000 feet then

the paper became ungainly long. Also

the early clear plastic readers were very large and anything but easy to use to

quantify the log resistivity readings.

Some of the early men to experiment with this type of log plotting were

Dr. C. E. Hottman and R. K. Johnson, Shell research and drilling personnel, and

a few geologists in the New Orleans office of the old Humble Oil and Refining

Co. which is today Exxon Company. Dr.

W. E. Wallace, Forest Oil Company, published his ideas in 1964 and 1965 in the

Oil & Gas Journal. W. R. Matthews

and John Kelly, Mobil Oil Company, also were in the early pioneer group working

on pore pressures from electric logs.

One of the pioneers on drilling problems in general and on

pore pressure evaluation in particular was Eugene S. Pennebaker, Jr. He was employed by Humble in the south Texas

Division in Corpus Christi. He did

considerable work and research on seismic data to determine formation pressures

before the well was drilled. This work

was published in the SPE landmark paper #2165 entitled “An Engineering

Interpretation of Seismic Data”. From

his original study of 350 well velocity surveys or check shots, he developed

several pressure readers. The first and

one used in his paper was for use with seismic interval velocities; the second

one was for use with the sonic log called an acoustic reader (or overlay). The one most used in South Texas was his

conductivity reader developed for the Miocene Frio formation wells that Humble

Oil was drilling on the King Ranch and adjoining leases at that time. In our practice we will use modifications of

his acoustic and conductivity readers as well as other proven methodology.

Some Industry News

Drill Abnormal Pressure Safely

By Leo J. McClure, Guest Columnist, Baird Petrophysical Newsletter

Practical field interpretation of data is the main thrust of

this newsletter and this column. Knowledge of certain geological principles and

physical laws are helpful in the understanding of the science of abnormal

pressure, but the actual interpretation of the drilling data generated at the

wellsite is an acquired art based mainly upon experience. Therefore, this

column is written expressly for drilling personnel --- roughnecks, drillers,

toolpushers, drilling superintendents, engineers, geologists, service company

personnel --- or any other person associated with boring a hole into the earth

to find hydrocarbons.

Hopefully, this newsletter will give you the knowledge to

recognize overpressured formations while you are drilling. And you can avoid

fire, killed or injured persons, junked holes, severely damaged oil and gas

reservoirs, and loss of time, equipment and money. Literally, you can Drill Abnormal Pressure Safely.

This newsletter is not a cook book for drilling a

difficult, overpressured well. It does not replace common sense, sound

reasoning, or proven detailed procedures for a specific job. Above all, the

manual will not make you an instant expert on abnormal-pressure drilling;

expert status is achieved only through extensive study and on-the-job

experience.

You will learn some basics of how to predict, detect, and

evaluate abnormally pressured formations, and how to solve the resultant

drilling and casing problems.

Recommendations for Improving Exploration in Overpressured Areas, Part I:

Overpressures – Pressure and Temperatures

by Paul E. Pilkington, Guest Columnist, Baird Petrophysical Newsletter

Engineers and explorers working together can supplement

conventional structural data with additional information derived from seismic

structure maps, seismic velocity analysis, offset drilling data and wireline

logs. These methods have been presented at various seminars for the past

several years.

These methods involve using pressure, temperature, and

wireline log data in addition to seismic mapping and velocity analysis. These

methods can determine depth cut-offs, areas where modified seismic techniques

may be required for seismic stratigraphy studies, and areas of poor source

potential in overpressures. In addition, statistical analysis of probabilities of

encountering sands with sufficient thickness and permeability for economic

rates appear feasible.

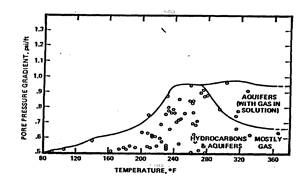

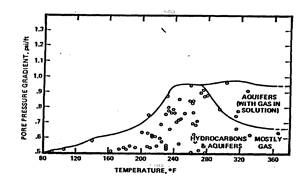

Figure 2. Deep

overpressured reservoirs fall into a temperature-pressure envelope.

Deep overpressured prospects have been evaluated for the

past several years using the Timko-Fertl pressure-temperature chart shown in

Figure 2. In all of the deep wells drilled into the temperature-pressure

envelope area noted as aquifers, no commercial hydrocarbons have been

encountered.

The chart shown in Figure 2 applies solely to clean Tertiary

clastic sediments offshore Louisiana and Texas. It does not apply to

areas offshore Texas where calcareous sands are found, because the consolidated

sands can fracture and create additional storage volume. It does not apply to the

deep Smackover and Norphlet areas, because generation and trapping mechanisms

are different.

Pressures and temperatures can be estimated from seismic,

drilling and wireline data. Seismic mapping and velocity analysis can be used

to help extrapolate offset data into the proposed location.

This chart can be used within

an area to determine the maximum depth cut-off’s for exploratory drilling and

enable more effective use of the exploratory dollar. One major oil company

completed a study about two years ago, which indicated one exception to

the envelope from all deep Louisiana wells drilled to that date. It is reported

to be slightly outside the line. However, my personal experience of monitoring

drilling for 27 years offshore and making pore pressure plots for 35 years has

failed to find the one well, which is reported to be the only exception.

Effect of Dip on Abnormal Pressure

By Ralph W. Baird, President, Baird Petrophysical International. Inc.

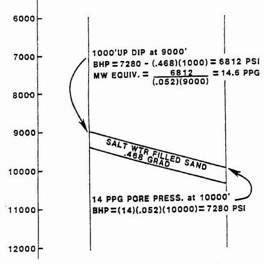

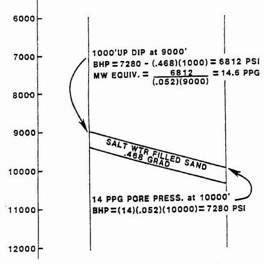

Figure 3 illustrates the effect dipping beds have on pore

pressure in abnormally pressured formations. Moving up-dip results in higher

pore pressure gradient in mud weight equivalents (equivalent mud weight, or,

EMW). This fundamental, simple relationship when used with seismic structural

mapping, offset wells and seismic velocity analysis can help remarkably to

estimate the expected pore pressure at the proposed well location. The same

process works in reverse when you move down-dip.

Figure 3. Effect of

dip on formation pore pressure.

STANDARDS or

the lack thereof: A continuing column

by Ralph W. Baird, President, BPI

Most of us have probably experienced the frustration and

potential errors faced when trying to compare data from separate wells where

the plots, data, scales and presentations all seem to collaborate to make the

comparison either impossible or dangerously misleading. You may even have a desk drawer full of

overlays, none of which seem to be on the scale and units of the data you are

attempting to interpret. This column

will discuss how some of these tools came to exist, why it is of extreme

importance to have a semblance of standards, and how we are going to accept

these standards.

The most basic area of standards is also the oldest—metric

or Imperial (English) units?? Our

industry has made a concerted and effective effort to move to the metric system

used by most of the scientific and governmental world. But we have to realize we have left

behind some important people who have either chosen not to commit to metric, or

who may not have been provided the tools necessary to make this transition.

An ever present and important part of our work is our

communications with the rig crew who are actually operating the rig and whose

cooperation and input we desperately need to drill any well safely and

efficiently. Many if not most of these

personnel are not well versed in the metric system. If we are to communicate information to these critical personnel,

we must do so in the terms they are most comfortable using. In most cases these are Imperial (English)

units — i.e., lbs/gal, ft/hr, psi, pounds, or Tons. If any of these personnel happen to be uncomfortable with

conversions, which BPI has actually witnessed, they may make a wrong guess, or

translation, which could lead to serious, well control problems

BPI Newsletter is

published monthly and freely distributed and copied by Baird Petrophysical

Group, Inc., 1784 W. Sam Houston Pkwy N., Houston, Texas 77043-2723.

Disclaimer:

The results discussed herein

are based on interpretation of drilling engineering, geological, geophysical

and other scientific data supplied to Baird Petrophysical by its various

customers on a private basis. It is the

Reader’s responsibility to value its use.

Baird Petrophysical specifically disclaims and does not warrant any of

its news, comments, interpretations or opinions about the information presented

here.

Mailing Address for BPI:

BPI Baird Petrophysical

1784 W. Sam Houston Pkwy N.

Houston, TX 77043-2723

Communication with BPI:

Tel: (713) 461-1784

Fax: CALL

Email:

Web: www.bairdpetro.com

Publications of BPI:

BPI Newsletter, by BPI Staff.

Simple Seismics, by Nigel Anstey.

Drill

Abnormal Pressure Safely, by Leo J. McClure.

Shallow Seismic Safety Study, by Ralph W. Baird, et al.

Seismic Interval Velocity Analysis, by Leo J. McClure.

CopyrightÓ2000-2008

Baird Petrophysical Group, Inc.

BPI NEWSLETTER

BPI NEWSLETTER

![]() Issue Number 1

Issue Number 1

![]()